Tube Inspection techniques

Home »

Tube Inspection techniques

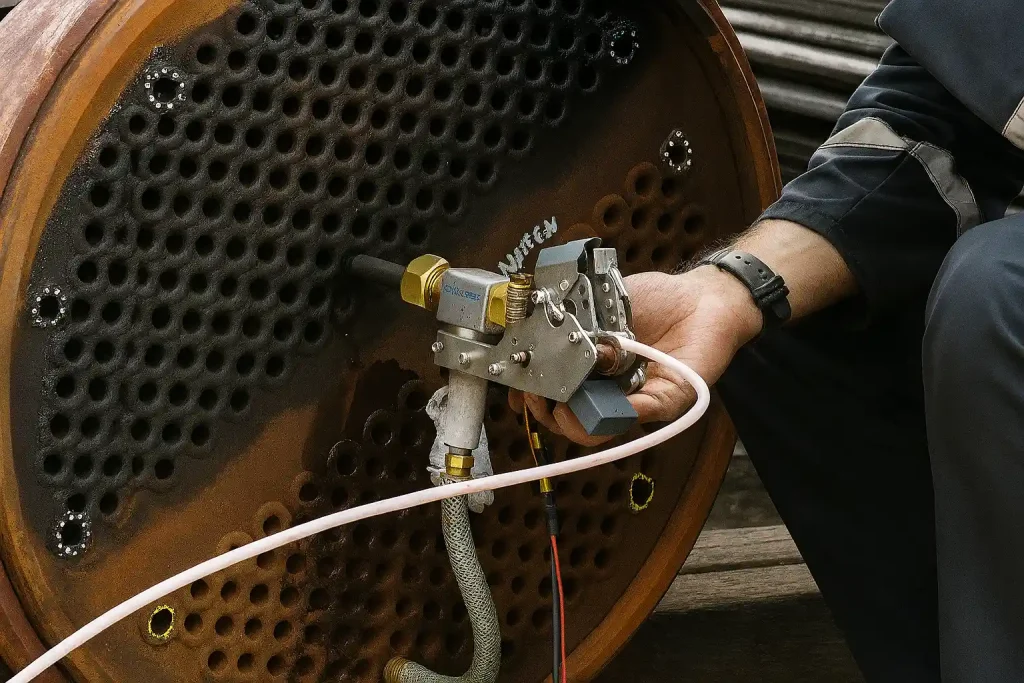

Tube inspection techniques are essential non-destructive methods used to assess the integrity and condition of heat exchanger, boiler, and condenser tubes in industries such as power generation, petrochemicals, and refineries. Eddy Current Testing (ECT) is widely used for non-ferrous tubes, detecting surface and near-surface flaws using electromagnetic induction. Remote Field Testing (RFT) is suitable for ferromagnetic tubes, offering deep penetration and sensitivity to internal and external defects. Magnetic Flux Leakage Testing (MFL) involves magnetizing the tube and detecting leakage fields caused by flaws, ideal for corrosion and pitting detection. Near Field Testing (NFT) is optimized for detecting internal corrosion and erosion in finned carbon steel tubes. Eddy Current Array (ECA) enhances traditional ECT by using multiple coils to provide faster, high-resolution scans of tube surfaces. Internal Rotary Inspection System (IRIS) uses ultrasonic testing with a rotating transducer and water column to deliver accurate wall thickness measurements and detect internal flaws. These advanced methods ensure reliable tube health assessments, enabling preventive maintenance and reducing the risk of failures.